Hard Anodizing

Hard Anodizing is the process which imparts hardness to aluminum by way of natural oxidization. Aluminum being light in weight and with its flexible adoptability to various engineering processes proves itself as a right option for various applications where making machines, components or products of lighter weight is of prime importance.

Hard anodizing overcomes the biggest drawback of aluminum i.e. its softness. In this process we can impart hardness upto 1000VPN which is as hard as steel, the coating layer leads in low ware and tare of the metal and also prevents it from corrosion and atmospheric attacks.

APPLIACTIONS

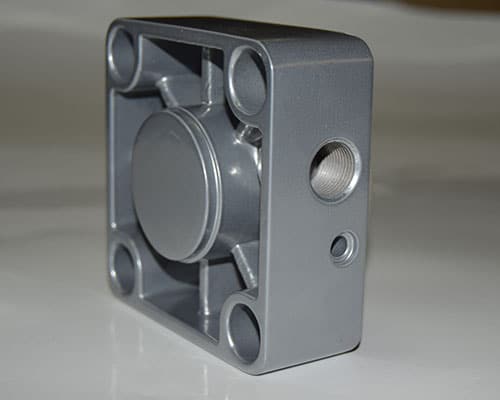

Hard Anodized components are widely used in automobile pistons, Cylinders, High RPM pulleys, Cone Pulleys for Textile Industries, Medical Equipments, Pneumatic Valves, Actuators,

Linear Motions, Sliding Parts, Hinges Mechanisms, Cams, Gears, Aircraft assemblies, Household hardware and Cookware etc.